Application Scenarios:

Hisurp direct expansion air handling unit is DX cooling unit widely used in:

*industrial workshops in pharmaceutical, chemical, mechanical, electrical, food, garment industries

*waiting and longue rooms in railway/train stations, airports

*apartments, CBD buildings, exhibition halls and meeting rooms

*schools, cinemas, theaters and hospitals

*hotels, malls, supermarkets and other commercial buildings

Parts:

Hisurp direct expansion air conditioner/ DX cooler has:

◆ compressor, expansion valves, heat exchangers, fans and electrical components from well-known brands

◆ composite steel and aluminum frame with higher hardness. 83.7% harder than aluminum and 63.9% harder than steel.

◆ box deformation <4mm/m under 1000Pa, European standard D1

◆ self-contained stainless steel drain pan, good heat isolation

◆ optional functions such as multi-fan, continuously adjustable airflow, anti-corrosion coating etc.

◆ rain-covered and has also technique against sun rays and corrosion.

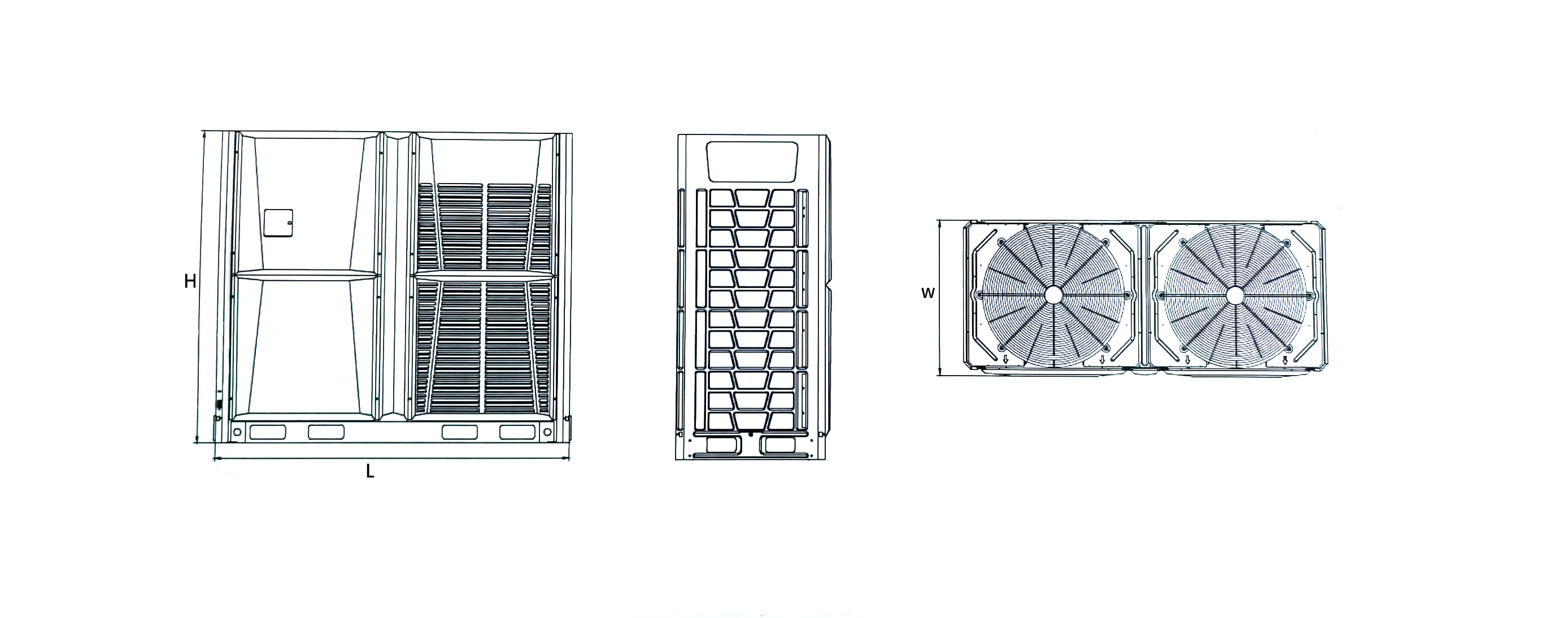

Diagram Preview (26-32HP):