Application Scenarios:

Hicon direct expansion air handling unit is DX cooling unit widely used in:

*industrial workshops in pharmaceutical, chemical, mechanical, electrical, food, garment industries

*waiting and longue rooms in railway/train stations, airports

*apartments, CBD buildings, exhibition halls and meeting rooms

*schools, cinemas, theaters and hospitals

*hotels, malls, supermarkets and other commercial buildings

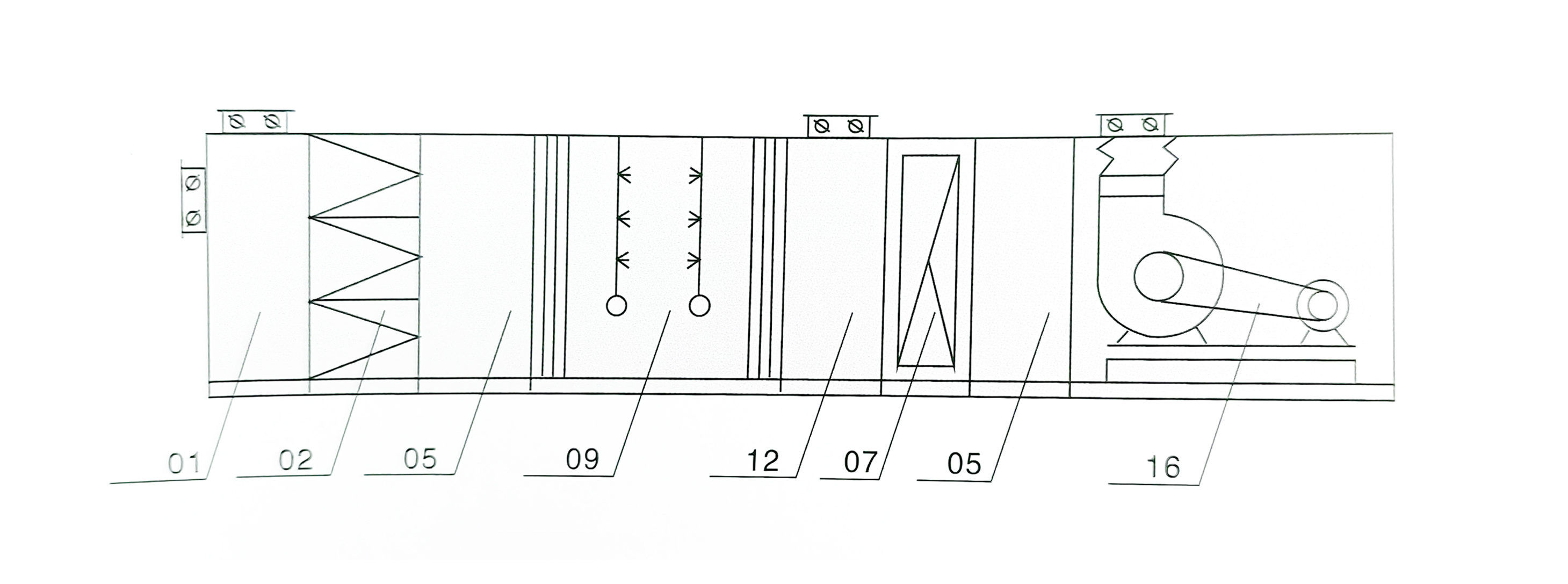

Parts:

Hicon direct expansion air handling unit/ DX cooler has:

◆ aluminum shell with panel and pole treatment, panel thickness 30mm. double-panel structure, compact structure, smooth and flat surfaces to keep clean.

◆ aluminum alloy strip frame. The bottom frame is welded with rigid or bent parts,of 63, 80, and 100mm in height.

◆ aluminum alloy regulating air valve, and air valves with sealing gaskets on the upper edge of the valve blade and the edge of the panel can be supplied according to needs.

◆ two or three air mixes and air valves. If not needed, flange or cover plate available, and the cover plate can be opened according to the size.

◆ different types of filters and parameters for selection: initial effect filter, medium efficiency filter, all aluminum and stainless steel air filter, high-efficiency HEPA filter, activated carbon filter, electrostatic filter, etc.

◆ finned coil heat exchanger of refrigerant direct expansion coil type, equipped with a condensate water pan. The standard coils can be 2, 4, 6, 8 rows, and the fin pitch 8, 10, 12 pieces/inch.

◆ electrical heating for heating in winter and dehumidification in summer, easy to install and maintain.

◆ humidifier with choices of dry steam humidifier, electrode humidifier, electric humidifier, wet film humidifier, etc.

Diagram Preview: