Applicaiton Scenarios:

Hicon Marine Air Conditioner is widely used in:

*marine vessels, on board, ships

*offshore

Parts:

Hicon Marine Air Conditioner has:

◆ compressor with deep oil tank design to ensure the oil supply of the compressor in the inclined and rocking environment on the ship. With special anti-corrosion paint

◆ water-cooled condensers use heat exchangers made of Bfe30-1-1 materials with strong anti-corrosion quality, and a liquid storage bag is added to ensure the liquid supply. Safety valve added. Air-cooled & water-cooled available.

◆ plated steel shell added to the outer surface to enhance the corrosion resistance of the evaporator. Air-cooled & water-cooled available.

◆ high-efficiency centrifugal fan and high-quality motor with anti-corrosion coating and anti-tilting even when the ship is periodically tilted up to 45°.

◆ the marine casting welded as a whole to meet the requirements for strength, anti-impact and anti-corrosion.

◆ reliable systematic components such as sight glasses, pressure gauges, solenoid valves, shock absorbers, etc.

◆ special marine duct design with return air boxes at air inlet and outlet

◆ frame and outer parts of cooled seawater pipeline painted to prevent corrosion. Electrical components made of anticorrosive materials and with electromagnetic interference protection.

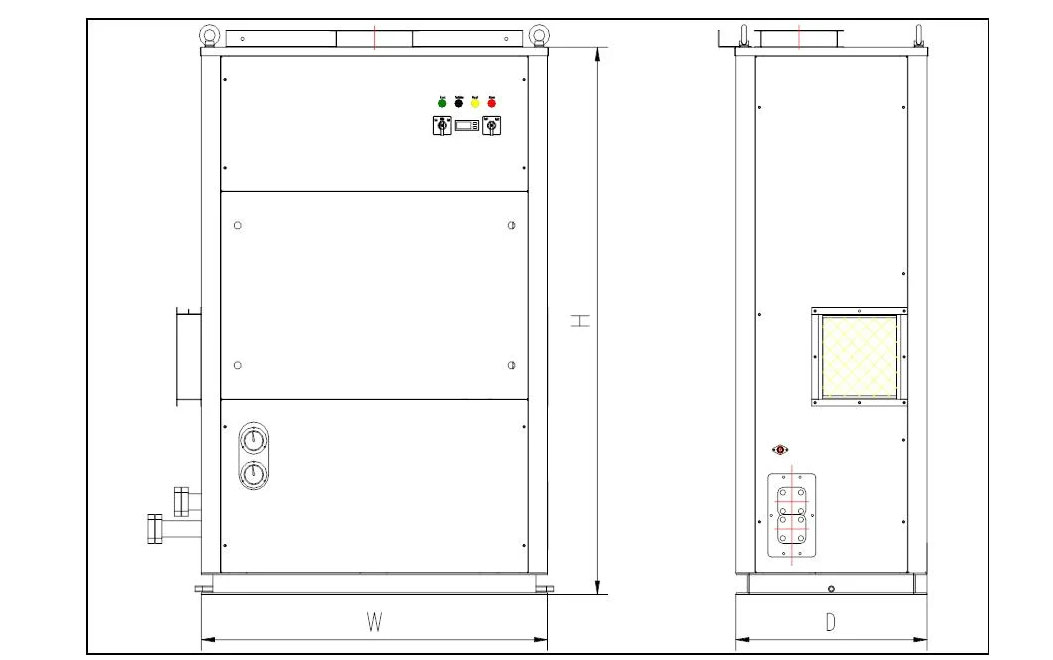

Diagram Preview (Water-cooled Marine Air Conditioner-top air supply (R404A)) :

◆ specially designed for Galley with capacities 6, 10, 14, 17, 20, 27, 35, 42, 50kW