Application Scenarios:

Hicon industrial fluid cooler is widely used for:

*CNC lathes, high-speed lathes,

*CNC machining centers, CNC grinders, broaching machines, milling machines

*hydraulic cooling machines

*woodworking engraving machines

*glass plants and various industries needing chilled water.

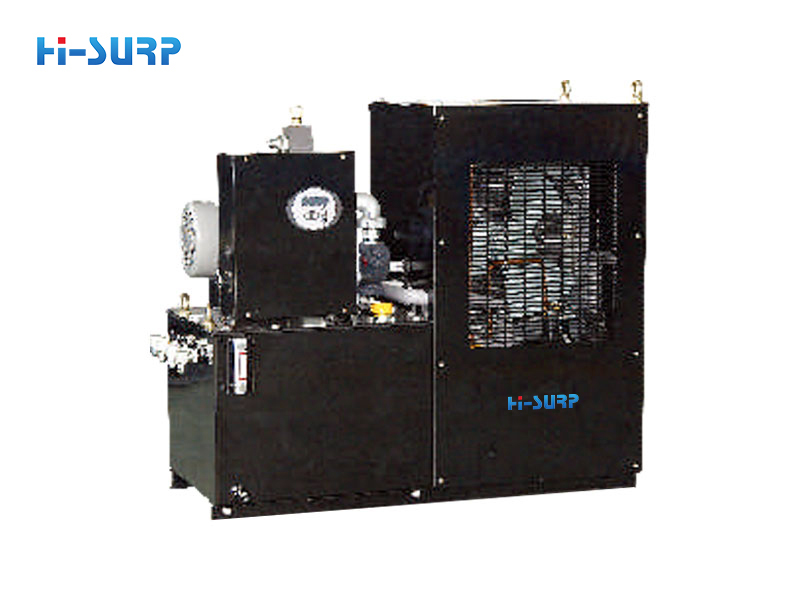

Parts:

Hicon industrial oil chiller has:

◆ refrigeration system, fluid cooling system and automatic control system

◆ functions to prevent CNC machinery from affecting processing due to changes in oil temperature.

◆ functions to prevent oil shock and deterioration of oil quality, and keep the viscosity of lubricating oil unchanged to stabilize the spindle movement.

◆ normal refrigeration mode and differential temperature mode: a synchronization temperature control panel to keep the oil temperature synchronized with the room temperature to prevent thermal expansion and contraction of the mechanical structure.

◆ automatic troubleshooting system connected to the computer to inform the fault in time.

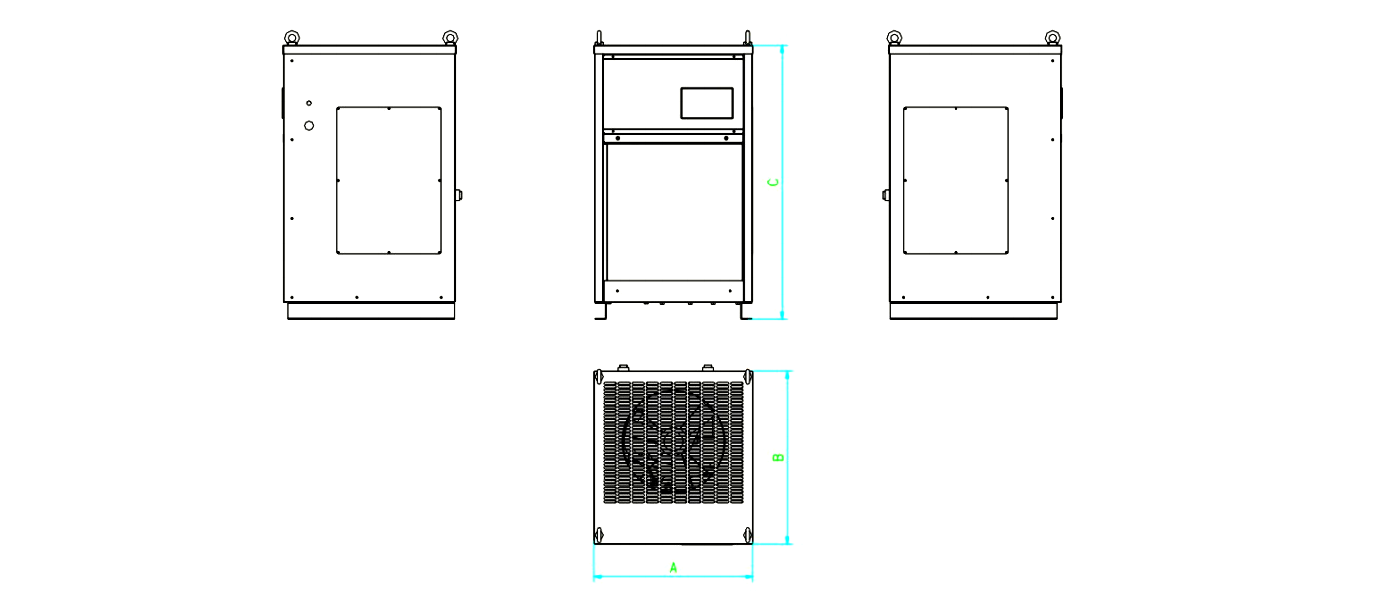

Diagram Preview (HY-B):